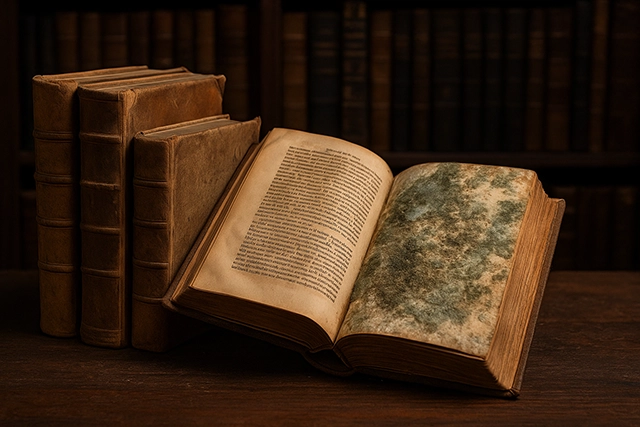

Fungal Contamination in Eye Drops: A Public Health Concern

Fungal contamination in ophthalmic products, particularly preservative-free eye drops, poses a serious public health risk. Recent cases involving contaminated artificial tears have resulted in severe eye infections, corneal damage, and permanent vision loss. The contamination highlights weaknesses in aseptic manufacturing, packaging integrity, and quality control. This article examines the microbiological risks, manufacturing vulnerabilities, and regulatory implications associated with fungal contamination in eye drops. Preventive strategies, including advanced aseptic technology, rigorous packaging testing, and robust microbial monitoring, are discussed to strengthen industry practices and protect consumer safety.

The Contamination Incident

In December 2024, the U.S. Food and Drug Administration (FDA) reported fungal contamination in specific batches of a well-known brand of preservative-free artificial tears. While initial testing revealed no immediate adverse events, subsequent cases linked the product to severe fungal keratitis and vision loss. A voluntary recall was initiated, underscoring the importance of stringent sterile production environments in pharmaceutical manufacturing.

Source: FDA, 2024

Health Impacts of Fungal Contamination in Eye Drops

Eye drops are formulated for direct ocular application and require absolute sterility. Contamination can lead to fungal keratitis, presenting with redness, discharge, blurred vision, photophobia, and ocular pain. If untreated, infection can progress to corneal ulceration and permanent blindness. Immunocompromised patients face heightened risk, as fungal pathogens may disseminate systemically.

Manufacturing and Packaging Failures

- Aseptic Manufacturing Gaps – Sterile facilities must maintain HEPA-filtered air, controlled humidity, and validated cleanroom procedures. Any deviation increases contamination risk.

- Packaging Integrity Issues – Single-use vials must be sterilized and sealed to prevent microbial ingress. Defective or improperly sterilized packaging can compromise sterility post-production.

- Quality Control Deficiencies – Microbial testing of raw materials, in-process samples, and final products is essential. Lapses can allow contaminated products to reach consumers.

Regulatory Oversight and Industry Standards

Regulatory bodies, including the FDA (U.S.) and TFDA (Taiwan), enforce Good Manufacturing Practices (GMP) for sterile ophthalmic products. These guidelines address cleanroom design, personnel hygiene, and microbiological testing. However, contamination incidents indicate the need for:

- More frequent inspections of manufacturing sites

- Enhanced testing for high-risk products

- Stricter penalties for GMP violations

Preventive Strategies

- Enhanced Aseptic Technology – Automation, real-time environmental monitoring, and isolator-based filling systems reduce contamination risk.

- Comprehensive Packaging Testing – All packaging components must be tested for sterility, material integrity, and contamination resistance.

- Rigorous Quality Control – Rapid microbial detection methods should be integrated into production lines for real-time sterility assurance.

- Consumer Education – Instructions on hygiene, proper storage, and disposal can reduce contamination risks during use.

Consumer Safety Guidelines

- Inspect packaging integrity before use

- Store products away from direct sunlight and heat

- Wash hands before application

- Avoid contact between dropper tip and ocular surface

- Discard opened containers promptly

- Never use products past expiration date

References

- U.S. Food and Drug Administration (FDA). (2024). FDA announces recall of contaminated artificial tears. https://www.fda.gov/

- Thomas, P.A., & Kaliamurthy, J. (2013). Mycotic keratitis: Epidemiology, diagnosis and management. Clinical Microbiology Reviews, 26(3), 557–598. doi:10.1128/CMR.00064-12

- World Health Organization (WHO). (2016). Guidelines on the quality, safety and efficacy of pharmaceutical products. https://www.who.int/

- McDonnell, P.J., & Taban, M. (2009). Contamination of multi-use ophthalmic solutions in clinical practice. American Journal of Ophthalmology, 147(5), 890–894.e1. doi:10.1016/j.ajo.2008.12.025

- Taiwan Food and Drug Administration (TFDA). (2023). GMP guidelines for sterile pharmaceutical manufacturing. https://www.fda.gov.tw/