Even metal also get mold? Don’t worry, YCM can hlelp!

When people think of mold, they usually imagine damp walls, textiles, or wood. But did you know that even metal parts can get moldy?

At YCM — the Global Mold Authority with over a decade of applied mold prevention across industries — our microbiology laboratory recently investigated a surprising case of mold growing on auto parts.

Why does mold grow on metal?

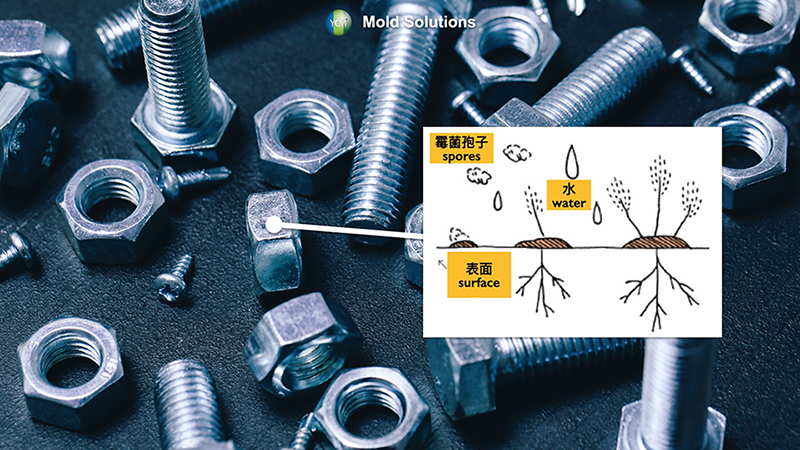

Normally, mold needs three conditions to thrive:

- Humidity above 60%

- Temperature between 25–35°C

- Nutrients such as carbon and nitrogen

The U.S. Environmental Protection Agency (EPA) emphasizes that controlling moisture is the key to mold prevention(EPA: Mold and Moisture).

Although metal itself does not provide nutrients, in real-world manufacturing, parts are often coated with oil layers to prevent oxidation. Over time, these oils — combined with dust, airborne organic particles, or other residues — create the perfect nutrient base for mold spores.

How mold survives on seemingly “inert” surfaces

- Even tiny traces of nutrients can sustain explosive mold growth.

- Airborne dust particles often carry organic matter rich in carbon and nitrogen (WHO: Indoor Air Quality – Dampness and Mould).

- If metal surfaces remain unclean for extended periods, or if oil films are not properly treated, spores can land, adhere, and colonize.

- Once environmental humidity and temperature reach the right levels, mold colonies become visible on the surface.

YCM’s role in solving the problem

Our YCM Microbiology Laboratory identified the root cause of moldy auto parts through systematic data analysis. By conducting laboratory simulations, environmental measurements, and preventive evaluations, we provided clients with practical solutions.

This approach is consistent with international standards for fungal testing such as ISO 846: Plastics — Evaluation of the action of microorganisms, which assesses material susceptibility to microbial growth.

Thanks to this process, our clients not only solved immediate issues but also established long-term preventive measures, ensuring that metal components remain mold-free throughout their lifecycle.

Conclusion

Mold is not limited by material type — it adapts to the environment. That’s why industries from textiles to automotive trust YCM to provide scientific evaluation and reliable prevention strategies.

For further reference on mold health and prevention, see:

Disclaimer: This article is intended for educational and industrial awareness purposes only. It does not constitute medical advice. Data and cases are based on YCM laboratory findings and internationally recognized testing standards.

Join YCM official Line account, let us answer your questions in detail!